Bale opening

To process opened natural and synthetic fiber bales, the standard bale opener with 1,500 mm working width is used. The feed apron can be adjusted to the dimensions of the production facility. This newly designed component is part of the modular system for fiber opening.

High-performance bale openers are available for high-performance applications based on natural and synthetic fibers. An automatic bale feeding system to accommodate a bale lay-down of up to ten bales is optional.

Bale Opener BO-A

- Automatic bale opener for specific applications

- Particularly suited when using bleached cotton or viscose as main fiber component

An optional bale tilting device is used to supply a bale opener with complete bales.

Weighing systems

With the newly developed pan weigher and the reliable belt weigher, the new system includes a discontinuous as well as a continuous solution. Both systems convince with their high production output and extremely high measuring accuracy, thus restricting the addition of fibers to the necessary minimum.

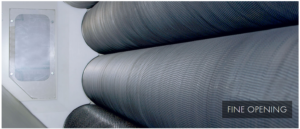

FINE OPENING: Supreme quality

Fine openers ensure that coarse fiber tufts are gently opened into smallest tufts or even single fibers.

Featuring two large feed rolls and an opening roll with spikes, the Trützschler reserve trunk TBL-FB is the first choice for the additional opening process. It works without clamping, thus minimising fiber strain.

Due to the high requirements of bleached cotton, other natural fibers such as flax, kenaf and hemp as well as recycling fibers, the special Fine Opener TBL-FO is used in these applications.

In some cases the fine opener allows the use of roller cards with less carding points. This reduces investment costs and increases productivity. For selected end products, even direct bonding is possible without a roller card.

BLENDING: Highest degree of homogeneity

Blending is crucial in determining the quality and processing characteristics of the material in downstream processes. The blending components from Trützschler Nonwovens are designed to ensure homogeneous blending even at high throughput rates.

Tuft blending installations optimally blend fibres of different types, lengths, finenesses and colours. Depending on production capacity, fiber type and end product, they are available in different sizes and two different systems: the large capacity blending bin TBL-BB and the blending system with movable chamber mill TBL-CM.

Both systems are individually adjustable, easy to operate, reliable and dependable. Thus, a large number of different fibers are processed with absolute homogeneity.

ADDITIONAL EQUIPMENT: Success is also a matter of flexibility

Accessories for the entire production process

Our claim to offer complete nonwoven systems is also met by a program that has the suitable accessories for each process step:

Metal separator

Automatic metal detection and separation system for reliable protection of the machine against damage caused by metal parts contained in the fiber material

Oiling system

Integrated in the pipeline, the oiling system is used to selectively moisten fibers with lubricants and antistatic agents.

Edge opener

During operation, this special opener opens the edge material that was cut off and extracted and returns it to the web forming system.

Diverter pipes

Auxiliary equipment such as switch pipes, T-distributors, material distributors, pipe shutters, and dust and fiber separators required for the pneumatic transport of fibers.

Bagging device

For intermediate fiber storage in big bags.

Fans

Designed in different sizes for pneumatic transport of fibers, based on required air volume and desired production capacity.