SAN™ SF & SNK SF – perfect for staple fibers

Circular Knitting

When using staple fiber yarns on large diameter circular knitting machines, accumulations of fiber residues, fiber abrasion, dirt and other yarn components can result in deposits in the channels of the needle carrier.

The special application needle SAN™ SF and Sinker SNK SF effectively reduce dirt accumulation and significantly extend cleaning intervals. The result is increased productivity and reduced production costs.

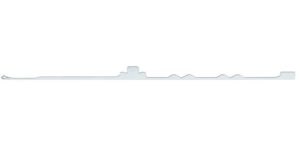

Special application needle SAN™ SF

The SAN™ SF special application needle is characterized by two special features: a needle shaft closed at the bottom and support cushions to support the cylinder walls.

Advantages of the SAN™ SF special application needle:

• Reduced contamination of the needle tricks

• Longer cleaning intervals and reduced machine downtimes – optimal results in combination with sinker for SNK SF staple fibers

• Even loop structure and increased productivity

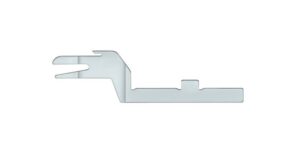

Sinker SNK SF

The sinker SNK SF for staple fibers is characterized by a special technical feature; an opening on the front part of the sinker. This achieves a self-cleaning effect.

Advantages of the sinker for staple fibers SNK SF:

• Reduced contamination of the sinker tricks

• Longer cleaning intervals and reduced machine downtimes – optimal results in combination with special application needle SAN™ SF

• Even loop structure and increased productivity

Needles with dur™ technology

Legwear

Sock and hosiery machines are highly complex systems, which, in turn, have to master complex production processes. This not only requires high-quality needles, but also a wide range of perfectly coordinated system parts.

Needles with dur™ technology are a further development of the Groz-Beckert sock needle for use under high loads and are characterized by increased hook stability, increased latch stability and a modified slit design.

Benefits of needles with dur™ technology:

• Reduced hook breakages and pulled hooks

• Reduction in bent latches and guaranteed latch movement, even with slightly bent needle latches

• Reduced machine downtimes and rejects – resulting in higher productivity

The right tool for any occasion

Flat knitting

The range of products that can be produced on flat knitting machines is varied, with potential for countless additional applications. To make use of this potential, needles and system parts are required, that are capable of fulfilling the requirements for producing these products. The SAN™ TT needle specially designed by Groz-Beckert for technical applications is an example of such a development.

Advantages of the SAN™ TT needle for technical textiles:

• Reduced hook breakages due to increased hook stability

• Safe spring-loaded function

• No hairy product surface thanks to anti-shear effect when using continuous filament yarns

• Optimized loop cast-off due to narrow latch head for firm loops

We also offer suitable needles and system parts for knitting in extremely fine gauges – Groz-Beckert offers the right knitting tool for any application and occasion.

A well-coordinated team

Warp Knitting

With warp knitting, even the smallest irregularities can have a major impact on the product quality. A uniform loop structure can only be achieved with perfect warp knitting tools. This is why Groz-Beckert places great importance on precision and a system-oriented approach.

Weaving accessories: healds

Functional healds are the small but decisive detail for greater efficiency and productivity of the weaving machine.

Advantages of Groz-Beckert healds:

• Suitable for all standard weaving machine types

• High wear resistance thanks to lightweight and stable material – even under extreme requirements

• Lower friction and less abrasion of the warp material – resulting in reduced contamination of the harness

• Ideal interaction with automatic drawing-in systems

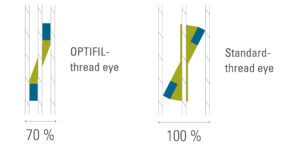

• Gentle transitions during changes thanks to the OPTIFIL thread eye

Advantages of OPTIFIL thread eye:

• Row densities up to 30% higher than with a standard thread eye

• Yarn-friendly transitions during changes

• Increased machine efficiency

• Reduced warp thread breakage

• Increased machine speed

Weaving preparation: the KnotMaster

The KnotMasters from Groz-Beckert are powerful knotting machines boasting the latest in technology and ease of use for different applications and different types of yarn, including cotton, synthetic and spandex. Customers benefit from rapid warp change and reduced idle times, and thereby from economical weaving preparation.

The advantages at a glance:

• User and maintenance-friendly modular system

• Compact design

• Single and double knots

• Up to 600 knots per minute

• Thread breakage monitoring