Animal skins have been made into leather for thousands of years. Leather was first used as clothing and in living quarters to ward off cold and other outside influences. Most of the leather made in the world today is used to produce footwear, but the hard-wearing material is also employed in the automotive and furniture industries.

The processing of technical textiles – that is, all textile-based products made primarily for their technical and functional properties and not for aesthetic or decorative purposes – has played a role in the textile world for only a few decades. The special requirements of this sector, such as the sewing of special materials or material combinations, also place high demands on production.

Sewing machine needles from Groz-Beckert provide many benefits when working with leather and technical textiles. Different cutting and cloth points, special application needles tailored to need, and innovative manufacturing methods lead to high reliability and flawless sewing results.

Special application needles SAN® 5.2

For the processing of technical textiles

Processing technical textiles often involves extremely hard materials or combinations of material. Penetration resistance can be very high and lead to various problems.

Groz-Beckert has been supplying the SAN® 5 special application needle for years, a reliable product that reduces sewing problems when working with technical textiles. The upgraded SAN® 5.2 boosts process reliability even more and delivers additional advantages, especially for multi-directional sewing applications.

The double groove at the point, for instance, leads to better thread guidance for a more consistent seam pattern. The additional scarf chamfer on the left side enables secure loop pick-up using oscillating hooks.

Learn more about the special application needle SAN® 5.2 in data sheet SAN® 5.2.

Special application needle SAN® 12

For perfect 2-needle decorative seams

Varying and irregular seams are among the problems known to crop up on 2-needle machines. Yet when manufacturing high quality leather products, high value is placed on the perfect pattern of fancy seams.

Irregular seams are caused by the different threading directions and loop pick-up of the left and right needles. Groz-Beckert has developed the special application needle SAN® 12 to improve the appearance of these 2-needle decorative seams.

This is achieved by exactly orienting the cutting geometry via a special flat on the shank. The two seams are matched for a more consistent appearance.

Learn more about special application needles SAN® 12 in data sheet SAN® 12.

Cutting points

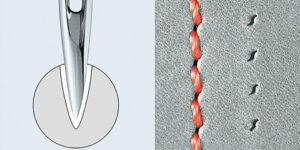

For creating different seam patterns on leather

Because of the structure of leather seam patterns vary, depending on sewing direction, when sewing with a cloth point. Leatherworking thus requires the use of a cloth point which produces a consistent seam pattern in all sewing directions. Groz-Beckert offers a wide variety of cutting points to allow for different seam appearances. Whether it’s the LR point for seams oriented to the right, the P point for marked fancy effects, or the S point for straight seams – creativity knows no bounds.

Learn more about the cutting points in data sheet Point styles for leather processing.

GEBEDUR®

The titanium nitride coating

Demanding sewing processes, such as the stitching of hard materials or combinations of materials, often lead to premature wear of sewing machine needles.

The special GEBEDUR® coating from Groz-Beckert gives the needle surface a higher degree of hardness. The titanium nitride coating makes the needle more wear-resistant, particularly protecting against damage around the point and eye. This extends the service life of the needle, ultimately leading to consistently high seam quality and increased productivity.

You might also like