Double the production rate, with lower energy consumption per kilogram of fiber material – that might sound like a contradiction, but the new Trützschler pre-cleaner CL-X makes it possible. It gently and reliably removes coarse contaminants like leaf debris, stalks or seeds from cotton with minimum loss of good fibers. The pre-cleaner CL-X provides more efficiency and lays the foundation for a high-quality end-product before the cotton is further processed in mixers and fine cleaners.

The new CL-X especially meets the urgent demand for lower energy consumption. Energy efficiency is not only important for environmental and regulatory reasons. Due to rising energy prices, it is becoming an increasingly decisive factor for the competitiveness of spinning mills.

The new Pre-Cleaner CL-X

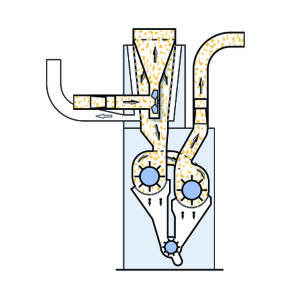

CL-X material flow

The new Pre-Cleaner CL-X

“During the development process, our main focus was on optimizing the fiber air flows. This is the area where we achieved the breakthrough. By forcing the air flow over two rolls, we have found a solution that allows lower power consumption at the opening rolls,” says Robert Többen, Head of Mechanical Engineering at Trützschler. “The fact that this flow is in the form of a spiral is also reflected in the name CL-X: The ‘X’ comes from the Greek word for spiral, Helix.”

In comparison with the current benchmark, the CL-X saves up to 30 % energy (see chart 1). In addition to the optimized flow, an integrated air separator contributes to reducing the transport air by ensuring that only excess air has to be removed, rather than all of the air. Less exhaust air means less energy consumption.

Chart 1: Energy savings CL-X vs. current benchmark

The CL-X also provides significantly increased productivity. At a maximum of 1,600 kilograms per hour, the production rate from one CL-X corresponds to the rate achieved by two CL-P models. This gives customers the flexibility to operate at high or low productivity rates with one machine.

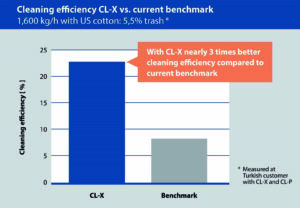

On top of this, the new CL-X is characterized by its excellent cleaning results. Trials conducted at a Turkish customer have shown that it reached a nearly three times better cleaning efficiency compared to the benchmark (US cotton, see chart 2). The improved grid geometry enables better separation and gentler tuft handling. Furthermore, a 2.60 m long cleaning section provides a maximum degree of opening and cleaning tufts.

Chart 2: Cleaning efficiency CL-X vs. current benchmark

The lot management system enables direct, automated coordination with the Bale Opener BO-P. The speeds of the opening rollers and the position of the grid bars – and thus the intensity of the cleaning – are automatically adjusted to the changing material fed (lot).

Due to the stepless and individual adjustment of grid devices for each opening roller, the machine can react to a wide variety of impurities. A 10 % higher speed of the second opening roller causes different speeds along the grids, while different sizes of waste can also be separated.

The WASTECONTROL waste sensor is now also integrated into the CL-X and makes sure that waste is reliably separated during production, which avoids unnecessary loss of valuable good fibers. The operator automatically receives a recommendation for the ideal setting via the machine’s display and can implement it with just a few clicks.

The CL-X is the perfect and sustainable solution to meet today’s demand for productivity, cleaning and energy efficiency.

CL-X features at one glance

• Continuous production of 1,600 kilograms per hour for present blow room configuration.

• 30% energy saving compared to the current benchmark.

• Integrated WASTECONTROL for automatic adjustment recommendation of waste excretion to avoid unnecessary fiber loss.

• 2.60 m long cleaning section.

• New and improved grid geometry for better separation and gentle tuft treatment.

• Material draft due to 10 % higher speed of second opening roller for reliable and consistent fiber transport.

• Optimal cleaning level and minimal fiber loss due to individual and stepless grid adjustment for each opening roller by motor.

• Gentle tuft treatment with adjustable opening roller speed.

• Synchronized lot management (automatic lot change for up to three lots).

• Connection possibility for a waste box (for waste analysis).

• Lower cost of ownership.

About Trützschler

The Trützschler Group is a German textile machinery manufacturer headquartered in Mönchengladbach, Germany. The family business is divided into the business units Spinning, Nonwovens, Man-Made Fibers and Card Clothing. Machines, installations and accessories for spinning preparation, the nonwovens and man-made fiber industry are produced in nine locations worldwide. In addition to four factories in Germany, Trützschler has production sites in China (Jiaxing, Shanghai), India (Ahmedabad), USA (Charlotte) and Brazil (Curitiba) as well as a development location in Switzerland (Winterthur). The company has a worldwide service network with service companies and centers in all important textile processing markets. For more information visit: www.truetzschler.com

Further visual footage

Scan the QR code and check out our new CL-X video on YouTube:

Contact

Trützschler GmbH & Co. KG

Postfach 410164

D-41241 Mönchengladbach

Website: