Automotive, Medicine & Apparel: Techtextil and Texprocess Innovation Awards transmit textile innovations and buying motivation to numerous branches of the industry

Frankfurt am Main, 20 June 2022. After a Corona-related break of three years, the

leading trade fairs Techtextil and Texprocess are once again presenting the

renowned Innovation Awards. The award-winning new developments from areas

such as New Products, Sustainability and Automation demonstrate: Textile

innovations and technologies provide impulses for many branches of the industry

and promise market and sales success far beyond their own sector. 13 winners

from seven categories will be honored at a public awards ceremony at Techtextil

and Texprocess on 21 June, 2022.

As is the case for many other industries, times are challenging for the textile industry: the

consequences of Corona, the Ukraine war, strained supply chains, sustainability issues,

rising energy prices and recruitment problems – the industry is under pressure from many

sides. But more than almost any other industry, it is also very adept at meeting these

challenges with new ideas, developments and business models. This year’s Innovation

Awards at the leading trade fairs Techtextil and Texprocess are another example of this.

With their new products, materials, solutions and processes, the 13 award winners are

demonstrating in an exemplary manner that textile innovations are the ideal way to create

market opportunities and boost future business revenues, out of the challenges of the

present.

World’s first: first woven heart valve without postfabrication

In the “New Product” category, the Techtextil Innovation Award goes to the Institute of

Textile Machinery and High Performance Material Technology (ITM) at the Technische

Universität Dresden. Together with medical product manufacturers and heart surgeons

from the Cardiovascular Center Würzburg and the Universitätsklinikum Würzburg, textile

researchers from the ITM have succeeded in developing the world’s first woven heart

valve that does not require a single seam or other joining technique. “Our new

development should also help children with heart valve defects in the future by growing

with the heart of the young patients – avoiding repeated surgical interventions,” says Dr.-

Ing. Dilbar Aibibu, research group leader for biotextiles and medical textiles at ITM.

Worldwide, cardiovascular diseases are among the most common causes of death;

several million people die from them every year. When patients receive heart valve

replacements, artificial mechanical or biobased solutions are usually used. If ITM has its

way, the woven valve, which won the Techtextil Innovation Award, should become a

beneficial alternative in the future.

Reuse of waste from a natural source

In the “New Material” category, RBX Créations (France) receives the Innovation Award for

a novel cellulose fiber made from hemp waste. The material, named Iroony® was

developed with regard to the following question: Hemp is now grown either to make fiber

or to produce hemp oil – but could not the two be combined? RBX Créations has now

succeeded in developing a process for extracting cellulose from the waste of oilseed

hemp. Spun into textile fibers, it can be used to produce sustainable textiles, packaging

and other “green” products. The award is given to RBX Créations for its continuous and

successful efforts to convert waste from a renewable source into a valuable cellulose fiber

that meets the highest sustainability standards.

Fiber shielding technology for hospitals, electric cars and server farms

The Techtextil Innovation Award in the “New Technology” category goes to Aachen-based

FibreCoat GmbH and Deutsche Basalt Faser GmbH from Sangerhausen (Saxony-Anhalt)

for the joint development of an aluminum-coated basalt fiber. It combines the strength of

basalt with the electrical conductivity of aluminum. According to FibreCoat,

electromagnetic shielding as wallpaper in buildings in hospitals or server farms, among

other places, should be up to 20 times cheaper than with conventional aluminum foil

thanks to the new development. Another attractive and particularly fast-growing market is

shielding solutions for electric cars. Robert Brüll, CEO of FibreCoat: “For a young

company like ours, winning the Techtextil Innovation Award is an important milestone. We

are honored to receive this prestigious award from the independent jury of experts. In

particular, the confidence of our customers and visibility gained as a result are crucial for a

start-up like FibreCoat on the road to market success.”

More sustainable hygiene products such as diapers

Kelheim Fibres GmbH from Kelheim in Bavaria and the Saxon Textile Research Institute

(STFI) in Chemnitz receive the Techtextil Innovation Award in the “New Concept”

category for the development of novel, thermally bonded nonwovens based on cellulose

for the production of reusable products with high absorbency. Consumers should no

longer have to choose between high-performance or environmentally friendly products.

Nature and performance of hygiene products go hand in hand thanks to the innovation of

Kelheim, STFI and the Berlin-based start-up SUMO. Dr. Marina Crnoja-Cosic, Director

New Business Development at Kelheim Fibres: “It is a great honor and pleasure for us to

receive the Techtextil Innovation Award together with our partners. We see the award not

only as a distinction for the project presented, but also as recognition of our innovation

strategy. After all, in dialogue with partners we can react more quickly to current trends,

develop in a more targeted manner and accelerate the commercialization of innovative

solutions.”

Waste from the automotive industry as a resource

Another Techtextil Innovation Award in the category “New Approaches on Sustainability &

Circular Economy” honors a process that uses natural leather waste from the automotive

industry to produce innovative textile coatings. It was developed by CITEVE, the

Technology Center for Textile and Clothing in Portugal, and partners ERT Têxtil Portugal,

CeNTI and CTIC (all Portugal). After CITEVE researchers discovered that cutting

operations in the automotive industry generate a large amount of natural leather classified

as waste, they sought a solution to reuse it. The expert jury recognizes the development

as a successful industrial symbiosis: “Waste from one industrial sector is used here as a

resource in another. The work of the CITEVE researchers thus supports an important

trend toward a resource-efficient, environmentally friendly and sustainable textile

industry.”

Compostable textile coating

The Techtextil Innovation Award in the category “New Approaches on Sustainability &

Circular Economy” goes to the textile research institute Centexbel (Belgium) for a biobased and compostable dispersion for textile coatings and printing inks. The new

development does not require solvents and brings a completely new type of polymer for

coatings and printing inks to the market. According to the expert jury, the innovation is an

important step for the textile coating industry towards more products based on renewable

resources.

Fashion from pineapple peel

The Italian company Vérabuccia is honored in the “Performance Fashion Award” category

for an innovative production process for the fashion and design sector. The patented

process is designed to transform fruit waste into fashion highlights. A first material is the

so-called “Ananasse”. According to Vérabuccia, the special feature of this is that unlike

other plant leathers, which tend to imitate real animal leather, it retains the original

appearance of a pineapple skin; this emphasizes the origin of the raw material. With the

Techtextil Innovation Award, the jury honored the unconventional thinking of the young

Italian label, whose originality proves that innovative and appealing fashion can be

developed from surprising materials.

100 percent compostable binder for nonwovens

In the “New Technology” category, the company OrganoClick (Sweden) receives the

Techtextil Innovation Award for the development of a 100 percent bio-based binder for

nonwovens applications that is made from waste components and is therefore said to be

fully compostable. The innovation is designed to replace plastic-based binders. Because

nonwovens are often made from non-degradable plastics, the Swedish company

specializes in developing compostable material alternatives from wheat bran, fruit or crab

shells, among others. This convinced the jury of the Techtextil Innovation Awards:

“OrganoClick receives the award for its efforts to find bio-based raw material alternatives

to replace oil-based materials.”

Formaldehyde-free & bio-based coating system

The third award in the category “New Approaches on Sustainability & Circular Economy”

goes to Deutschen Institute für Textil- und Faserforschung Denkendorf (DITF) from

Baden-Württemberg and the company TotalEnergies – Cray Valley (France). Together,

they have developed a novel, formaldehyde-free coating system. It is based on non-toxic

hydroxymethylfurfural (HMF) derived from biomass waste. These HMF-based dip

formulations are capable of replacing formaldehyde-based adhesion promoters on a oneto-one basis. For background: in tires, conveyor belts or V-belts, rubber materials are

reinforced by cord. The quality of such cord composite systems with high-strength fibers

such as polyester, aramid or polyamide and rubber is determined by the adhesion

properties of the fibers to the matrix. In the established manufacturing process, adhesion

promoters made of resorcinol-formaldehyde-latex (RFL) are used. However,

formaldehyde has been classified by the EU as a proven carcinogen and mutagen since

2014. The jury therefore welcomes the health and environmentally friendly new

development. It contributes to a more sustainable textile industry and the reduction of

harmful chemicals.

Texprocess Innovation Award

In the “New Technology” category of the Texprocess Innovation Award, as many as three

winners will receive the prestigious award this year:

Cold gluing robot is set to revolutionize seam bonding

The welding and sewing machine manufacturer Vetron Typical Europe GmbH

(Kaiserslautern) is being honored for a new type of cold gluing robot. For the first time, it is

to perform the sealing of seams with adhesive tape on the reverse side completely

automatically. Cold gluing, for example for decorative seams on dashboards or closing

seams in outdoor clothing, is state of the art in many industries. But because the adhesive

tape has to be cut off manually, the technology could not be combined with the high

demands of process automation, for example in the automotive industry. Until now. For

the first time, the new special robot applies the adhesive tape in an automated process

and also cuts it off automatically using a tape cutter. According to Vetron, the innovation,

which was presented publicly for the first time at Texprocess, is already attracting great

interest from the automotive industry.

“Reinvention of the embroidery head”

The second award in the “New Technology” category goes to ZSK Stickmaschinen GmbH

from Krefeld for a new type of embroidery head for single- and multi-head embroidery

machines. According to ZSK, the “R-head” is designed to achieve embroidery speeds of

up to 2000 stitches per minute. By comparison, traditional multi-head embroidery

machines currently achieve embroidery speeds of up to a maximum of 1200 stitches per

minute. With this innovation, ZSK aims to enable a new dimension of productivity with

higher embroidery precision and reliability even at high embroidery speeds. According to

ZSK, the R-head significantly reduces noise emissions compared to current embroidery

heads. Customers should also be able to replace it themselves if necessary. The

judgment of the expert jury: “This is the reinvention of the embroidery head.” HansRochus Groß, Head of Application Technology at ZSK: “During the development of our

latest embroidery head, we were driven by a quote from Hermann Hesse: ‘To achieve the

possible, we must attempt the impossible.’ In this sense, the Texprocess Innovation

Award confirms that we have achieved our ambitious goals. The award will be an

additional drive for us to continue to achieve ‘the maximum possible’ for our customers in

the future.”

Increasing productivity and reducing fatigue of sewing machine operators.

The third winner in this award category is Juki Central Europe (Poland), which has

developed an AW-3S automatic bobbin thread winding and feeding device. This not only

automatically calculates the amount of bobbin thread required when loading a sewing

pattern, but can even change the sewing thread automatically, according to the

manufacturer. AW-3S is thus designed not only to increase productivity, but at the same

time to save operators from having to change the sewing thread manually. This reduces

staff fatigue, allowing them to concentrate more on production and quality control. The jury

welcomes the conversion of a manual process into an automated one as another example

of Industry 4.0.

Advancing digitalization in the sewing industry

The industrial sewing machine manufacturer Dürkopp Adler receives the Texprocess

Innovation Award in the category “New Digitalization” for its software module “QONDAC

Guided Working”. The company from Bielefeld wants to take digitalization in the sewing

industry to a new level. In interaction with programmable sewing machines, QONDAC

Guided Working is intended to become the perfect link between planning, operating

personnel and machine by supporting processes from production planning to the last work

step at the final workstation. In addition, manual workstations or conventional sewing

machines can also be easily integrated into the network. Niklas Böckmann, Head of

Digital Products at Dürkopp Adler: “The Texprocess Innovation Award confirms us in our

claim to drive the digitalization of the sewing industry. With developments such as

QONDAC Guided Working, we want to make customers’ production more sustainable and

efficient by offering them the possibility to react faster to changes in production

processes.”

The jury of the Techtextil Innovation Award:

Prof. Dr. Fernando Carrillo, Universitat Politècnica de Catalunya (UPC), Spain

Eng. António Braz Costa, Technological Centre for the Textile and Clothing Industry

of Portugal (CITEVE), Portugal

Johannes Diebel, Forschungskuratorium Textil e.V. (FKT), Germany

Dr. Heike Illing-Günther, Saxon Textile Research Institute e.V. (STFI), Germany

Dr. Jan Laperre, Centexbel, Belgium (chairman of the jury)

Prof. Dr. René Rossi, Swiss Federal Laboratories for Materials Science and

Technology (EMPA), Switzerland

Dr. Thomas Stegmaier, Deutsche Institute für Textil- und Faserforschung (DITF),

Germany

Prof. Dr. Henry Yi Li, The University of Manchester, England

The jury of the Texprocess Innovation Award:

Alexander Artschwager, Deutsche Institute für Textil- und Faserforschung

Denkendorf, Center of Management Research (DITF-MR), Germany

Jürgen Brecht, HAUBER-GRUPPE FERD. HAUBER GMBH, Germany

Prof. Dr. Thomas Gries, Institut für Textiltechnik, RWTH Aachen, Germany

Prof. Dr. Yordan Kyosev, Institute of Textile Machinery and High Performance

Material Technology, TU Dresden, Germany

Claudia van Bonn, Deutscher Fachverlag, Germany

Walter Wählt, Adidas AG, Germany (chairman of the jury)

Prof. Dr. Kerstin Zöll, Hochschule Niederrhein, Faculty Textile and Clothing

Technology, Germany

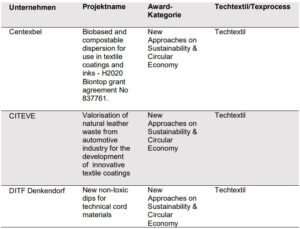

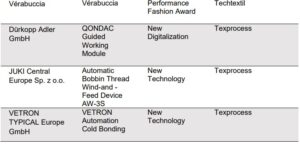

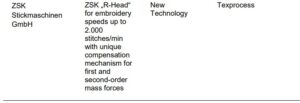

The winners and award categories at a glance

From 21 to 24 June only at Techtextil and Texprocess

The Techtextil and Texprocess Innovation Awards will be presented on 21 June, 2022 in

Hall 9.0. Textile innovations selected by international expert juries will be awarded prizes

and presented publicly on all four days of the trade fair in Hall 9.1 (Techtextil) and 9.0

(Texprocess), in some cases for the first time. Here, from 21-24 June, visitors will have

the unique opportunity to experience all the award-winning new developments in one

place. For the 16th time, the Innovation Awards at the leading trade fairs Techtextil and

Texprocess offer an excellent platform for cross-industry exchange between players from

business, science and politics and for initiating forward-looking cooperations.

The event Techtextil & Texprocess will be held from 21 to 24 June 2022.

Press information and photographic material:

https://techtextil.messefrankfurt.com/frankfurt/en/press.html

https://texprocess.messefrankfurt.com/frankfurt/en/press.html

Links to websites:

www.facebook.com/techtextil | www.facebook.com/texprocess

www.linkedin.com/showcase/techtextil | www.linkedin.com/showcase/texprocess

www.twitter.com/ttx_tp | www.instagram.com/techtextil_texprocess

www.techtextil-blog.com | www.texprocess-blog.com

Your contact:

Mira Engl

Tel.: +49 69 75 75-3060

mira.engl@messefrankfurt.com

Messe Frankfurt Exhibition GmbH

Ludwig-Erhard-Anlage 1

60327 Frankfurt am Main

www.messefrankfurt.com